How to ensure the accuracy and surface quality of camshafts during the manufacturing process of TOYOTA automobile camshafts?

Materials are the foundation. KORBOR uses high-performance alloy materials as the basic materials for camshafts. These materials have been strictly screened and have excellent mechanical properties and thermal stability, providing a solid foundation for subsequent processing and the performance of the final product. High-performance alloys can not only effectively resist high temperature, high pressure and high-speed friction during engine operation, but also maintain stable dimensional accuracy and shape stability in long-term use.

In terms of heat treatment, KORBOR uses a series of advanced processes, including tempering, carburizing and quenching, which are crucial to the performance improvement of camshafts. Carburizing can increase the carbon content on the surface of the camshaft, thereby improving its hardness and wear resistance; quenching changes the internal structure of the material through rapid cooling, further improving the hardness and strength; tempering is to eliminate quenching stress and maintain the toughness and comprehensive mechanical properties of the material. The combination of this series of heat treatment processes enables the camshaft to maintain high strength and hardness while also having good fatigue resistance and deformation resistance, laying the foundation for high-precision processing.

In the precision machining process, KORBOR uses advanced CNC lathes, grinders and grinding centers, which are equipped with high-precision measurement and control systems to ensure that every size and shape feature of the camshaft during the machining process meets the design requirements. In particular, for the machining of the cam profile, KORBOR uses high-precision CNC grinding technology, which ensures the accuracy and smoothness of the cam profile through precise programming and real-time monitoring, which is crucial for the timing of the opening and closing of the engine valves, and directly affects the power output and fuel efficiency of the engine.

In addition, KORBOR also pays attention to the control of surface finish, using fine polishing technology to remove tiny flaws and burrs generated during the machining process, improve the smoothness and wear resistance of the camshaft surface, reduce friction loss and noise during operation, and extend the service life.

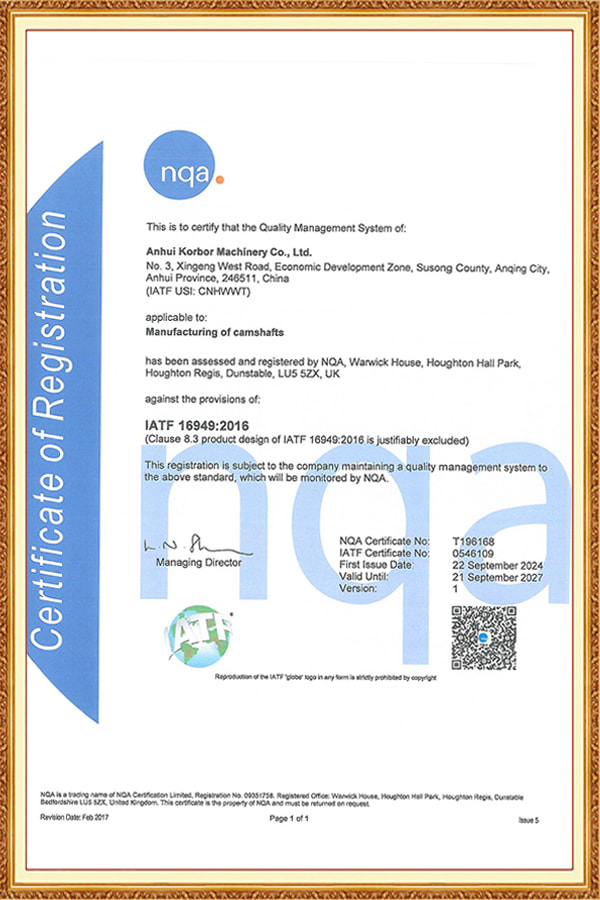

KORBOR follows the IATF16949:2016 quality management system standard, which is one of the most stringent international standards in the automotive industry, covering the entire process from design, production to service. By establishing a sound quality management system, KORBOR has achieved strict control of every link from raw material procurement, production and processing to finished product inspection, ensuring the consistency and stability of product quality.

The "zero defect" production concept is the core of KORBOR's quality management. The company emphasizes that prevention is better than correction, and eliminates potential quality problems through continuous improvement and preventive measures. During the production process, KORBOR implements multi-level and comprehensive quality control, including online monitoring, first-piece inspection, process inspection and final inspection to ensure that each batch of products meets the highest quality standards.

KORBOR not only provides high-quality camshaft products, but also is committed to providing one-stop service to each customer. From blank casting to finished product delivery, every link is strictly controlled to ensure reliable quality and timely delivery. This service model not only improves customer satisfaction, but also enhances KORBOR's competitiveness in the global market.

Every year, KORBOR delivers more than 2.3 million sets of products to customers around the world, including customized camshafts for TOYOTA cars. Through strategic cooperation with many internationally renowned brands, KORBOR has not only accumulated rich industry experience and technical strength, but also won wide recognition and trust in the global market.